PPE for the aggregates industry

The aggregates industry involves the extraction, processing, and distribution of materials such as sand, gravel, crushed stone, and recycled concrete for use in construction and infrastructure projects. This sector plays a crucial role in providing essential materials for building roads, bridges, buildings, and other structures. Due to the nature of the work, workers in the aggregates industry are exposed to various hazards, including falling debris, dust, noise, and heavy machinery. As a result, wearing appropriate personal protective equipment (PPE) is essential for ensuring worker safety.

At uvex, we are committed to safeguarding the well-being of individuals working in aggregates by providing comprehensive access to high-performance Personal Protective Equipment (PPE), along with value-added services and unparalleled support. Our mission is clear: protecting people.

- High-Performance PPE: uvex offers a wide array of PPE across multiple categories, including but not limited to, eye, hearing & hand protection, and footwear. Our products are meticulously designed and rigorously tested to ensure maximum protection against the hazards prevalent in the aggregates industry.

- Value-Add Services: We go beyond merely providing safety gear. Our value-add services encompass comprehensive safety assessments, on-site training programs, and customised safety solutions tailored to the specific requirements of each application and hazard encountered by workers in the field.

- World-Class Support: uvex is committed to supporting our customers at every stage of their safety journey. Our team of experts provides ongoing guidance, assistance, and troubleshooting to ensure that our customers have the resources they need to maintain a safe and compliant work environment.

Case studies

HexArmor® has worked with the aggregate industry for 20+ years and has active partnerships with some of the largest aggregate companies.

We work directly with you to solve problems and overcome hazards with our industry-leading solutions.

Hand safety for general maintenance

Chrome Series® 4027 - True aggregate glove

The issue: Besides experiencing high glove usage, maintenance workers were exposed to crush and pinch points, sharp metal edges, and abrasions.

The solution: Through an onsite assessment and collaboration, the Chrome Series® 4027 was developed as the “true aggregate glove,” combining high cut protection and abrasion resistance (provided by SuperFabric®) with high durability and impact.

The result: The TP-X® palm and fourchettes of the Chrome Series® 4027 have increased durability by three times the previous leather glove option, while repelling fluid and improving worker confidence.

Hand safety for falling debris, rubble and heavy object

Rig Lizard® 2025X

The issue: A 12-kilogram boulder fell from 3 meters onto a worker’s hand while clearing away debris and rubble. He was hospitalized for several days, away from work for eight months and spent a year rehabilitating.

The solution: A similar situation happened to another worker while wearing the Rig Lizard® 2025X and that worker was left untouched due to the resilient nature of the IR-X ® impact.

The result: The shock-absorbing materials of IR-X® impact have increased safety by absorbing blunt force impact from rocks and pry bars.

Hand safety for concreting

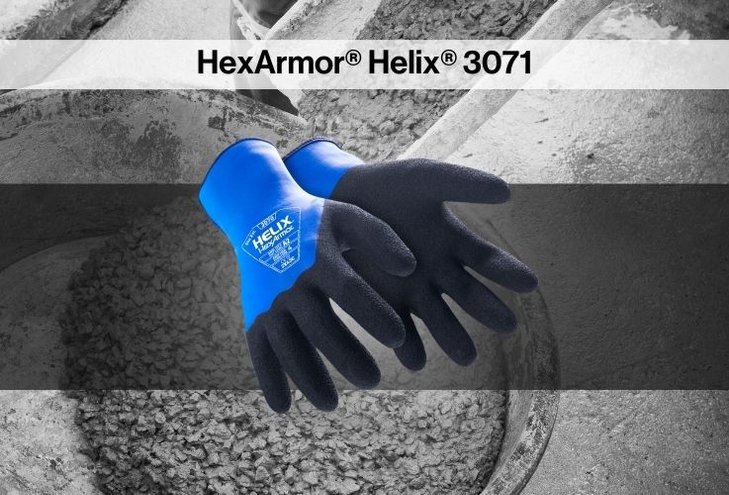

Helix® 3070 and Helix® 3071

The issue: If hardened concrete is left untreated on the skin, it can begin to blister, swell, and bleed – leading to first, second, and even third-degree burns. Severe cases of concrete skin irritation can lead to permanent scarring or skin grafts.

The solution: Investing in high-quality hand protection for this task is paramount. The Helix® 3070 and Helix® 3071 were designed for concrete handling. The protective qualities of the glove will remain intact, keeping hands safe and dry.

Hand protection from cuts with HexArmor®

Chrome Series® 4060

The issue: While performing routine screen change maintenance, a worker’s hand became caught between the exposed wire ends of the new screen and the older screen above it. The worker felt a pinch when pulling out their hand from between the screens.

The solution: The exposed wires cut through the exterior leather layer of the Chrome Series® 4060 but were stopped by the protective layer inside.

The result: The Chrome Series® 4060 reduced injuries and gave worker’s confidence and security when following screen change protocols.

Hand safety while working with fluids, lubricants & chemicals

Rubiflex S XG27BI

The issue: When handling and cleaning chutes several times a day, workers were exposed to pinch and cut hazards, as well as degreasers, lubricants, chemicals, fluids, fuels, and high-water pressure.

The solution: HexArmor® safety specialists recommended the HexArmor® Rubiflex S XG27BI, the “classic wash glove”, due to its liquid-resistant barrier and IR-X® back-of-hand impact protection.

The result: The HexArmor® Rubiflex S XG27BI NNR coating kept worker hands dry, while the Xtra Grip palm delivered exceptional grip, added durability, and increased longevity, providing over one month of use per pair.